Instructional Labs

-

Introduction to Mechatronics Engineering

Introduction

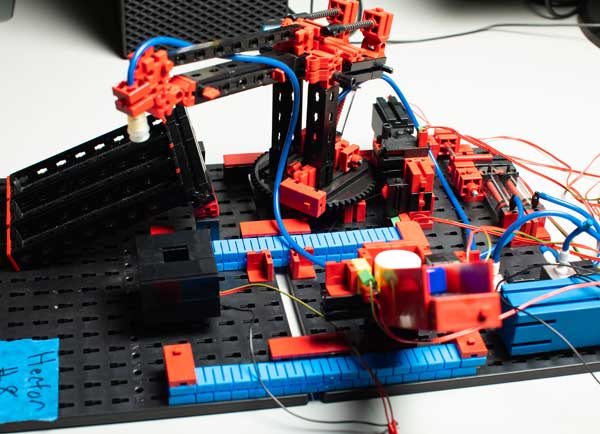

Introduction to Mechatronics Engineering Lab teaches students about robotics, by using

the VEX robotics platform, and gives hands on examples of how the different aspects

of STEM are all used in the field of robotics. This lab also introduces the VEX robotics

CLAWBOT, and uses it as a platform to introduce students to the different subsystems

within the VEX platform and how they interact together by using digital and analog

sensors. Students put this knowledge into practice as they follow step-by-step directions

to build their first robot, program it using remote and autonomous control and ultimately

participate in an in house VEX robotics competition.

Introduction to Mechatronics Engineering Lab teaches students about robotics, by using

the VEX robotics platform, and gives hands on examples of how the different aspects

of STEM are all used in the field of robotics. This lab also introduces the VEX robotics

CLAWBOT, and uses it as a platform to introduce students to the different subsystems

within the VEX platform and how they interact together by using digital and analog

sensors. Students put this knowledge into practice as they follow step-by-step directions

to build their first robot, program it using remote and autonomous control and ultimately

participate in an in house VEX robotics competition.

Hardware

Hardware

VEX robotic Kits- Software

RobotC

SolidWorks

Location: Engineering Technology Center, Building Q

Room Q-118 Dale Heatherington Mechatronics Lab

-

Intermediate Programming for Mechatronics

Introduction

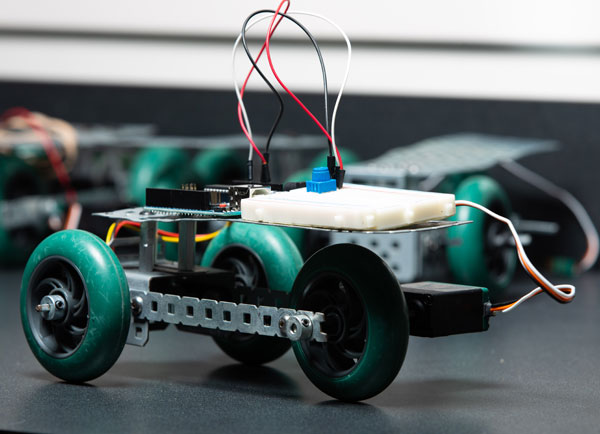

Intermediate programming for Mechatronics Lab covers programming topics relevant for Mechatronics Engineering, using tools such as C++, Arduino, and Python. The focus is towards acquiring analog, digital, and camera sensor data, motor control, pneumatics, etc. The lab also has a color sorting robot system, PI controlled minicars, DC motor control with Arduino, 2D tracking, serial communication, and image processing for students learning.

- Hardware

Color sorting robots

Minicars - Software

Anduino IDE

Python

C++

Location: Engineering Technology Center, Building Q

Room Q-242 - Hardware

-

Mechatronics Engineering Fundamentals

Introduction

Mechatronics Engineering Fundamentals Lab teaches fundamental skills for the mechatronics engineer.

Topics Include:

- Creating electronics circuits using diode, LEDs and Transistors.

- A mobile robot programming using the Robot Operating System (ROS).

- Perform robot kinematics with principles of obstacle avoidance.

- Sensors and actuators, especially pneumatics.

- DC motors programming and interfacing with the AVR microcontroller.

- Hardware

ROS bots

Pneumatics Test Bench - Software

Robot Operating System

Location: Engineering Technology Center, Building Q,

Room Q-118 Dale Heatherington Mechatronics Lab

Room Q-242

-

Fluid Power

Introduction

Fluid Power is the Robotics and Mechatronics course equivalent to Fluid Dynamics.

Fluid Power has a heavier focus in motors and pumps which is more useful to graduates

in our field. The lab focuses heavily on understanding and creating fluid simulations

and diagrams. Students will have the chance to examine hands on equipment such as

the FESTO Manufacturing Production system and to create fluid simulations from it

as well as work with and control the FESTO Process Control Training Bench. Students

will show mastery by being able to create many different fluid control simulations

using a variety of components.

Fluid Power is the Robotics and Mechatronics course equivalent to Fluid Dynamics.

Fluid Power has a heavier focus in motors and pumps which is more useful to graduates

in our field. The lab focuses heavily on understanding and creating fluid simulations

and diagrams. Students will have the chance to examine hands on equipment such as

the FESTO Manufacturing Production system and to create fluid simulations from it

as well as work with and control the FESTO Process Control Training Bench. Students

will show mastery by being able to create many different fluid control simulations

using a variety of components.

- Hardware

FESTO Manufacturing Production System(including Fanuc Robot)

FESTO Process Control Training Bench - Software

Fluidsim

Labview

Location: Engineering Technology Center, Building Q,

Room Q-118 and Q-110 - Hardware

-

Feedback Control

Introduction

This is a laboratory course designed to complement the modeling and feedback controls topics also covered in MTRE4001. Feedback Control (PID Control), Model Identification, MATLAB/Simulink Modeling, and Process Control are studied and analyzed using simulations and physical experiments.

- Hardware

Couple Water Tank System

Electro Motors - Software

QUARC- Realtime Control Software

MatLab

Location: Engineering Technology Center, Building Q,

Room Q-110 (water tank set up)

Room Q-336 (electromotor set up) - Hardware

-

Instrumentation and Controls

Introduction

Instruments and Controls teaches student the fundamentals of Programmable Logic Controllers

(PLCs). It uses a program called Totally Integrated Automation (TIA) portal to program

the Siemens PLC to do various tasks to demonstrate knowledge and understanding. Students

will have hands on learning and programming of PLCs as well as demonstrations and

hands on trouble shooting of the larger Kawasaki Robotic arms with fully integrated

Vanderlande Conveyor System. Students will demonstrate their mastery of their PLC

use with a culminating project of fully programming the MiniFESTO Pick and Place system.

Instruments and Controls teaches student the fundamentals of Programmable Logic Controllers

(PLCs). It uses a program called Totally Integrated Automation (TIA) portal to program

the Siemens PLC to do various tasks to demonstrate knowledge and understanding. Students

will have hands on learning and programming of PLCs as well as demonstrations and

hands on trouble shooting of the larger Kawasaki Robotic arms with fully integrated

Vanderlande Conveyor System. Students will demonstrate their mastery of their PLC

use with a culminating project of fully programming the MiniFESTO Pick and Place system.

Hardware

Hardware

Siemens PLC controllers

MiniFesto Pick and place system

FESTO Manufactiromg Production System (Including Fanuc Robot)

FESTO Process Control Training Bench

Kawasaki Robots and Vanderlande Conveyor System fully integrated

Integrated unit using Misubishi robot- Software

Totally integrated Automation (TIA) portal

Siemens Produc Lifestyle Management (PLM)

Location: Engineering Technology Center, Building Q,

Room Q-110

Room Q-118 Dale Heatherington Mechatronics Lab

Room Q121 -

Robotics Analysis and Synthesis

Introduction

Kinova Robotic Arm The “Robotics Analysis and Synthesis” course introduces coordinate transformations, kinematics/dynamics modeling, control system design, and path/trajectory planning of robotic arms. A state-of-the-art robotic arm, the Kinova arm, provides students a versatile and safe robotic platform to explore and validate the robotics knowledge learned from the classroom. The Kinova arm has 7 joints and a 3-finger robotic hand, which is adaptable for varying levels of expertise to test and perform simple or complex grasping and manipulation tasks. In addition, the course also utilizes ROS (Robot Operating System) to implement simulations and control of a robotic arm.

Hardware

The Kinova robotic arm

Software

ROS (Robot Operating System), MatLabLocation: Engineering Technology Center, Building Q

Room Q-242