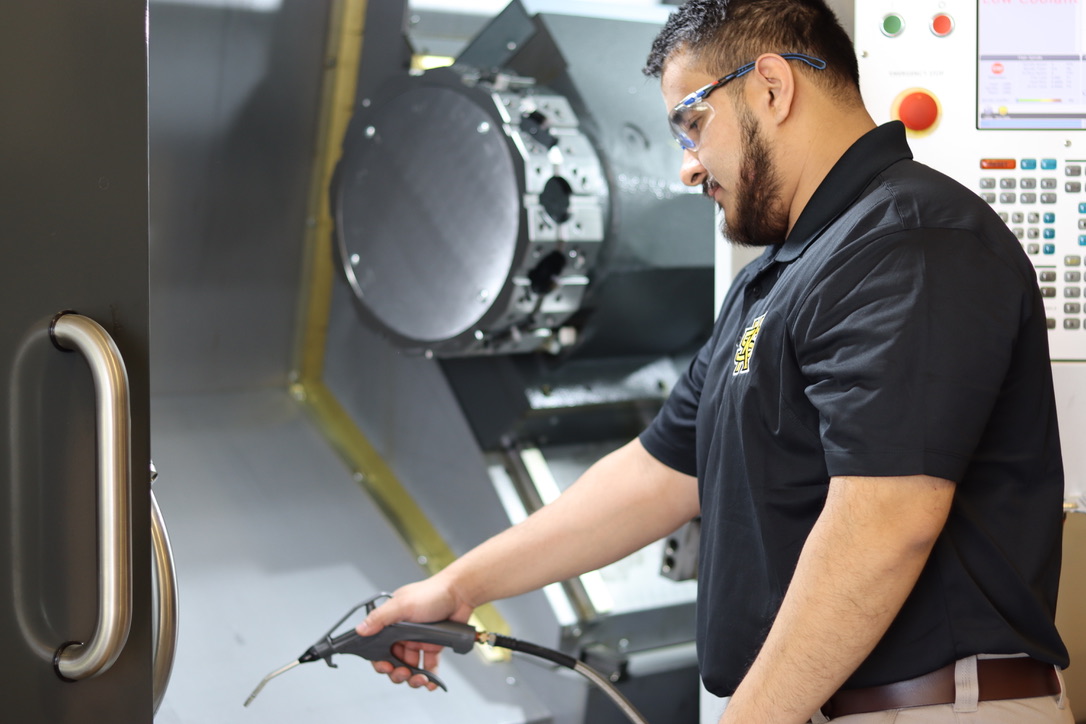

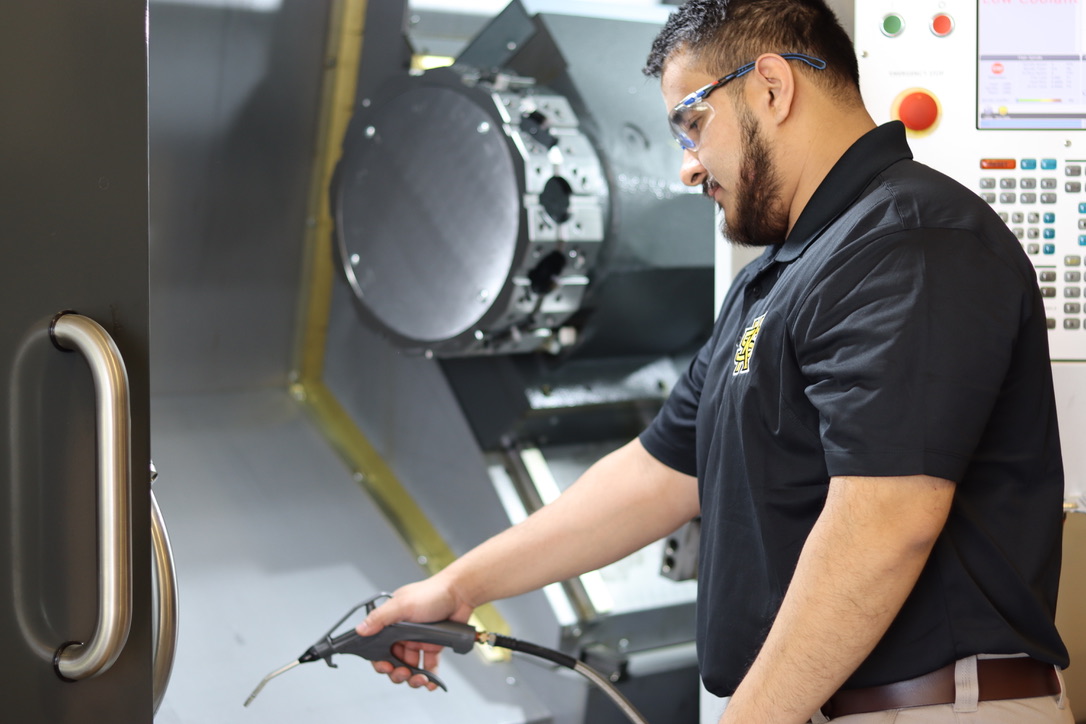

When setting foot in the high-tech Machine Shop at KSU’s Southern Polytechnic College

of Engineering and Engineering Technology (SPCEET), one is immediately captivated

by the drone of machines and the soft hum of lasers. For over seventy-six years, SPCEET

has been dedicated to imparting knowledge to our students about the practicality of

engineering, the ability to manufacture things, and the theoretical understanding

that aids in eliminating unnecessary steps in the manufacturing process. We aim to

produce manufacturing engineers equipped with technical skills and intellectual depth

who are ready to step into the industry as experienced professionals. Design for Manufacturability

(DFM) is the path to the future.

Given the growing globalization of supply chains and changing market demands, engineers

are trained to consider a product's lifecycle and usage, which often requires more

personalized products. The Machine Shop plays a pivotal role in shaping the future

of our students. This top-notch facility prepares our students for the professional

world with a curriculum that includes a two-semester program focusing on engineering

designed products and G Code programming. The objective is to instruct students on

the appropriate use of CNC machinery for Industry and product development.

A well-defined curriculum path ensures that students progress from novices to skilled

professionals, using machines from their first year to their Senior Design project.

In the course MET 1800 CNC Programming and Machining I, students are introduced to

G-code programming, machine usage, setup, and tool selection. The follow-on course

MET 2800 CNC Programming and Machining II builds on these fundamentals by integrating

Computer-Aided Design and Computer-Aided Machining to create tool paths for part creation.

"Our graduates are sought after by many companies to design, build, code, and test

through to a final product. This comprehensive preparation enables our graduates to

translate their experience into industry practice seamlessly," said Engineering Technology

Department Chair, Dr. David Stollberg.

Model-Based Manufacturing and Design for Manufacturability play critical roles in

preparing students for the modern manufacturing facility where time efficiency and

customer satisfaction are paramount. They equip students to design sustainable products

correctly the first time, a vital skill in keeping U.S. manufacturing at the forefront

of the global economy.

The Machine Shop significantly impacts our students by allowing them to bring their

theoretical creations to life. Holding their first part in their hands is a momentous

milestone where digital concepts meet reality. “As a Southern Poly Grad with nearly

40 years in Industry, I clearly understand how the combination of academic and hands-on

experiences at Southern Poly prepared me for career success. The recent investments

in our machining and welding labs expose our students to the latest manufacturing

technologies--reinforcing the potential for our student's success,” said Richard Kennedy,

Director of 3D Print Center and Senior Lecturer of MET.

By providing a platform for students to actualize their designs, the Machine Shop

has proven to be instrumental in shaping the future of aspiring engineers. Success

stories abound, such as those of Sam Obhi and Grace Miller, who have leveraged their

experiences in the Machine Shop to excel in their endeavors. The focus on Model-Based

Manufacturing and Design for Manufacturability ensures that graduates are well-versed

in the latest practices of modern manufacturing facilities.

“With over 30 years in the Industry and a Southern Poly grad, I've witnessed the evolution

of engineering and production processes. The need for high-quality, cost-effective,

and foolproof product design is more critical than ever in today's global market”,

said Tim Adams, Lecturer of MET.

Originally, our college was founded to bridge the gap between craftsman and engineer.

Today, Southern Polytechnic College of Engineering and Engineering Technology continues

the legacy of bridging the gap between craftsman and engineer, educating our graduates

in applied engineering and theoretical knowledge to streamline manufacturing processes.

Our goal is to nurture a new generation of engineers who are adept at translating

ideas into tangible products that meet customer expectations and industry standards.

-

Story by Shannon Uschold

Photos by Darnell Wilburn and Shannon Uschold